CNC turning stands as a cornerstone of modern precision manufacturing, offering unmatched versatility and efficiency for producing cylindrical components. Whether you’re developing aerospace parts or simple machine bushings, CNC turning provides an automated, high-accuracy method for shaping metal and plastic stock into finished products.

What is CNC Turning?

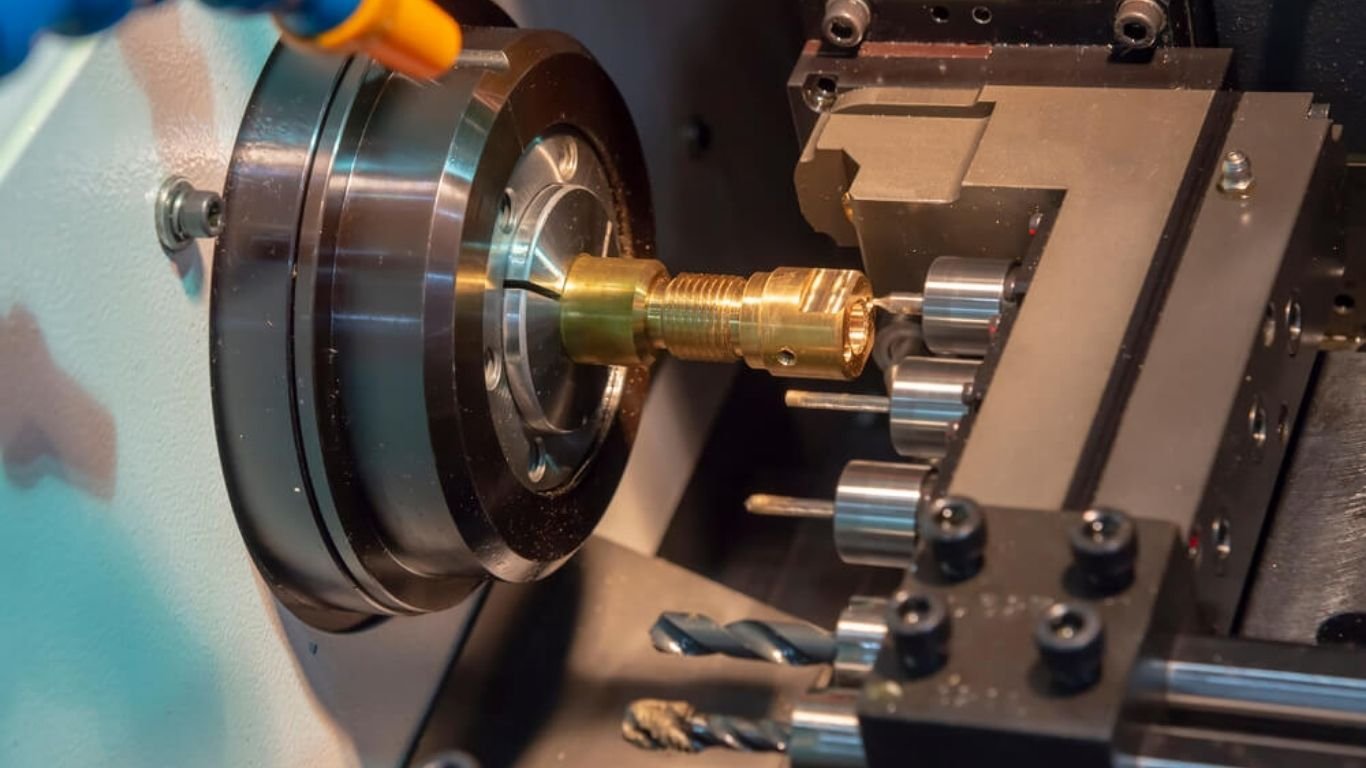

CNC turning is a subtractive machining process where a cutting tool removes material from a rotating workpiece. Unlike CNC milling—where the cutting tool rotates—CNC turning keeps the tool stationary while the workpiece spins, allowing for the creation of symmetrical parts like shafts, pins, and rings.

Most CNC turning operations are performed on lathes or turning centers. A CNC lathe typically handles two-axis (X and Z) movements for basic tasks, whereas a CNC turning center may incorporate additional axes, live tooling, and even milling capabilities, making it a more advanced and flexible solution for complex geometries.

Components of a CNC Turning Machine

A typical CNC turning machine consists of the following core components:

- Spindle and Chuck: The spindle rotates the workpiece, held securely by a chuck with three or four jaws.

- Tool Turret: This rotating fixture houses multiple cutting tools, automatically indexing them into position as needed.

- Tool Inserts: Made from hard materials like carbide or ceramic, inserts are selected based on the workpiece material and cutting speed requirements.

- Controller: A computer-based unit that interprets G-code instructions to control the movement, speed, and tooling sequences.

Advanced machines may also include bar feeders, coolant systems, and sensors to enhance productivity and maintain part quality.

Common CNC Turning Operations

CNC turning encompasses a variety of machining operations, each serving a specific purpose:

- Facing – Creating a flat surface at the end of a workpiece.

- Straight Turning – Removing material along the outer diameter.

- Taper Turning – Cutting a gradual change in diameter.

- Grooving – Forming recesses such as O-ring seats.

- Threading – Cutting helical threads internally or externally.

- Boring – Enlarging existing holes to precise diameters.

- Drilling – Producing axial holes with high precision.

- Knurling – Pressing textured patterns for improved grip.

Each of these operations can be customized via programming, allowing for repeatable results with tolerances often within ±0.005 mm.

Materials and Insert Technology

CNC turning is compatible with a wide range of materials—from aluminum and brass to titanium and hardened steel. To cope with varying hardness and heat generation, tool manufacturers have engineered advanced coatings and crystalline structures in their inserts.

For instance, cutting inserts with unidirectional crystal orientation (like Sandvik’s Inveio® technology) exhibit improved heat resistance and tool life. Such innovations reduce tool wear, lower manufacturing costs, and allow for higher cutting speeds without sacrificing precision.

Horizontal vs. Vertical CNC Turning

CNC turning machines come in two main orientations:

- Horizontal Turning: The most common configuration, ideal for small to medium-sized parts. However, it may be prone to vibration in heavy workpieces.

- Vertical Turning: Suitable for large, heavy components as gravity aids in stabilizing the workpiece. Chip evacuation, though, can be challenging.

The choice between horizontal and vertical setups depends on part geometry, weight, and desired surface finish.

Benefits of CNC Turning

CNC turning offers several clear advantages for both prototype and production environments:

- High Precision: Eliminates human error with automated, repeatable programming.

- Speed: Accelerates part production with minimal manual intervention.

- Safety: Keeps operators at a safe distance from rotating parts.

- Design Flexibility: Easily handles custom geometries and rapid tooling changes.

- Cost Efficiency: Especially when producing parts in medium to high volumes.

Applications Across Industries

CNC turning is vital in sectors such as:

- Aerospace – Complex shaft and turbine components.

- Automotive – Axles, gears, and custom fasteners.

- Medical – Surgical pins and orthopedic implants.

- Oil & Gas – Threaded pipe connectors and valve components.

- Electronics – Precision housings and connector sleeves.

Each application benefits from the dimensional control, repeatability, and material versatility CNC turning provides.

Final Thoughts

As the demand for tighter tolerances and quicker turnaround times grows, CNC turning continues to evolve. With innovations in multi-axis control, insert coatings, and software integration, manufacturers now enjoy unprecedented control over production processes.

Whether you’re machining a single prototype or scaling to full production, CNC turning offers a reliable, high-performance pathway to quality parts—every time.

Leave a Reply